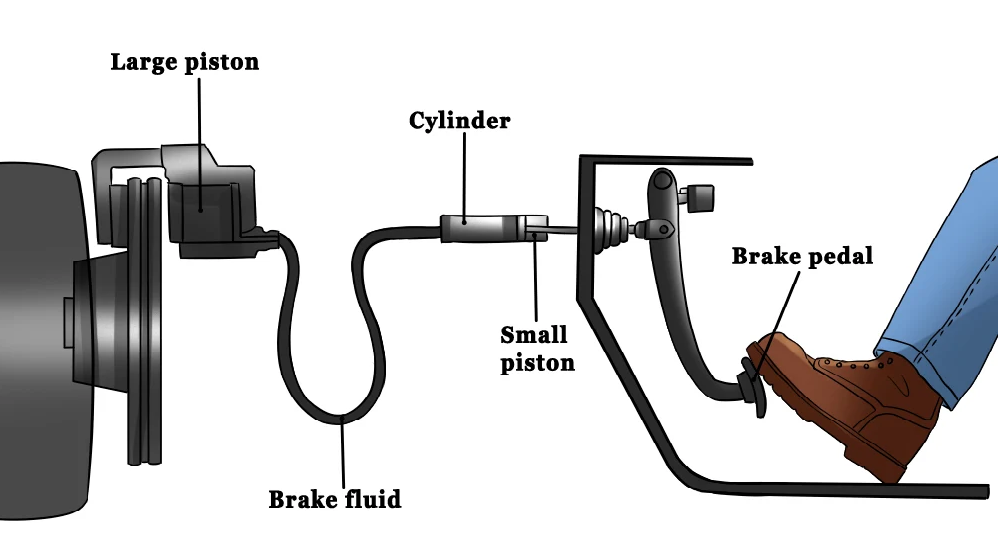

A Mechanical Braking System is a mechanism to control the moving object. It can slow or stop the speed of the vehicle. The force is transmitted from one point to another with the help of levers.

Functions of the Brakes

The primary function of the brake system is to slow or stop the vehicle speed. This is controlled by the brake pedals. When a person presses down the brake pads, the rotor that is attached to the wheel is controlled by the force. This is caused due to friction.

Types of brakes

There are various types of brakes classified according to the method of power, application, and operation.

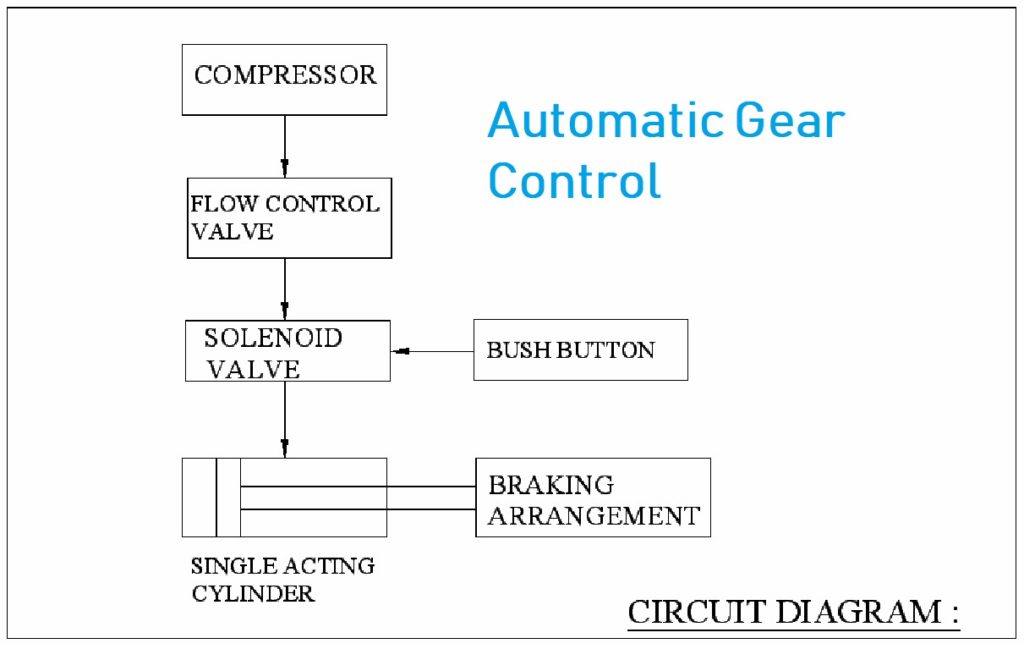

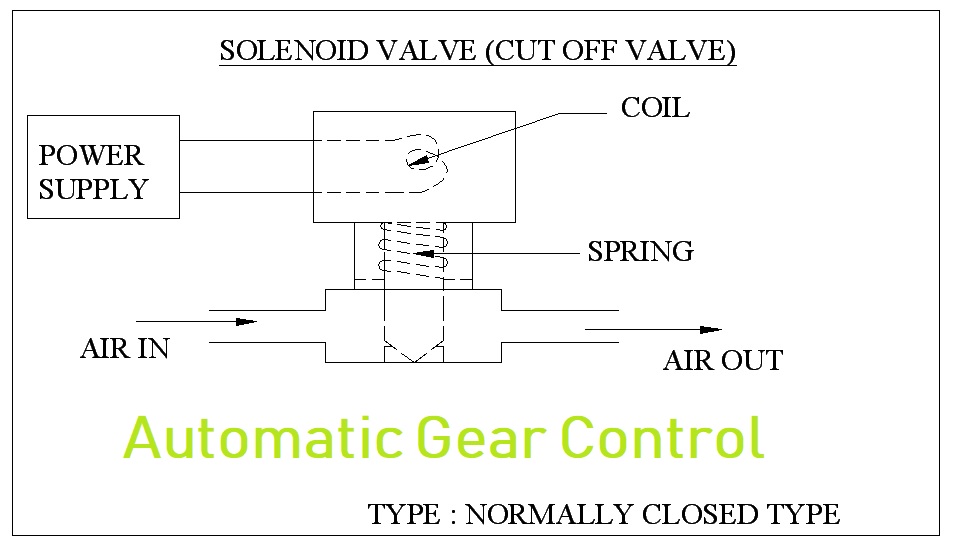

By the method of power: Mechanical Brakes, Hydraulic Brakes, Air Brakes, Vacuum Brakes, Magnetic and Electrical brakes.

By the method of application: Service and Parking brakes are classified under the application.

By the method of operation: Manual, servo, and power operation are classified under the method of operation.

Types of Mechanical Brakes

Drum Brakes and Disc Brakes are the main two types of mechanical brakes.

A disc brake is a mechanism for stopping or slowing the wheel while in motion. It is usually made up of cast iron. But it can also be made of ceramic -matrix composites reinforced carbon-carbon.

A drum brake is made up of a brake drum attached or jointed inside a drum. It is a mechanism where a person presses the pad, and the vehicle stops due to the friction from the rotating drum.

Other few types of mechanical brakes are brand brakes and cone brakes.

Brand brake is a brake mainly used for bicycles. It is a tightened high friction pulley attached to the rotating axle.

Cone brake is one of the types of the drum brake, where the cone and the drum are in mating sections.

The friction brake saves the heat in disc while the brake is pressed and carries out the air slowly. In some emergencies, the brake prevents the slowing down of the vehicle. When traveling down a hill, the brake spins the drum and releases a large amount of heat without the increase in temperature.

The design and the model of the mechanical braking system is a daring task for all engineers. The power of the braking system depends on the actuation force that is applied. Due to this force, the working surface experiences wear and friction. The breaking system decreases the forces and minimizes the friction. In this project, the study is on the best braking system by examining the defection and forces that are applied to the mechanical braking system for a simpler optimization process. It is very important to understand the action force and the friction that occurs and their performance to understand the nature of work to reduce the accident.

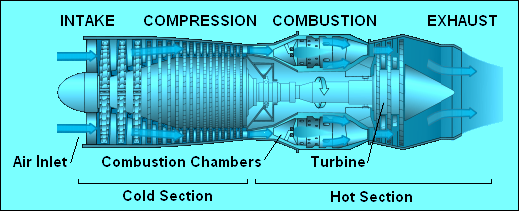

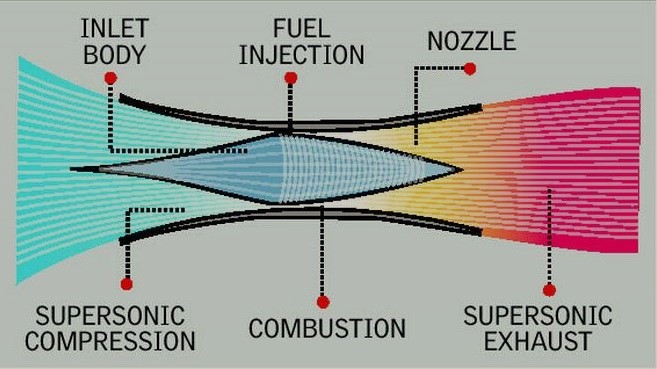

Brakes are usually used to move the axles and wheels. The vehicles engage the braking mechanism mainly for the racing cars. They are mainly used for wheel brakes, flights, helicopters, parachutes, and many other areas. In many brakes, friction is created from the kinetic energy to heat energy. The transformation of kinetic to potential energy is saved in the form of oil or air.

Conclusion

We have observed various methods of the mechanical braking system and its function in this project that helps in the daily works of engineers and other workers. In the analysis of brakes, it is observed that in the process of the braking system, one of the brake shoe displacement and force is bigger than the other side of the brake shoe. The mechanical braking system has been tested with 220lbs which is of good form. It is analyzed that the brake shoe force was in variation. The friction and displacement of the brake system are completely symmetric.